Understanding what radial-ply and bias-ply tires are and their strengths and downfalls is essential when it comes to choosing between the two.

Knowing the pros and cons of each will not only help you in purchasing your next tire, should that be your end goal, but build your understanding of automobiles.

Below is detailed information about these two tire types.

What Are Radial Tires?

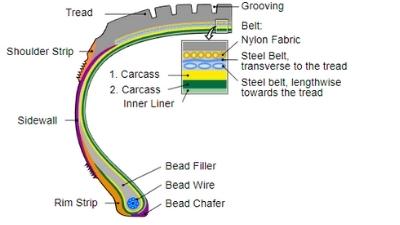

A radial tire is designed differently from other tire models. It is constructed using polyester threads running perpendicular from bead to bead, down each sidewall, and up over the face of the tire.

A belt running below the tread is on its face over the polyester covering. The belt width is nearly that of the tire and runs around the tire, providing a “squared” appearance to the tire.

Initially, belts used to be constructed from rubber-coated fibers, but almost all current belts are built from steel fibers. This gives the radial tires the name “steel-belted” radial. This belt helps reduce wear and stabilize the thread.

According to the tire construction, the sidewall always has a bulge when in contact with the surface. Due to that, people might think the tire is under inflated.

What Are Bias Ply Tires?

The term bias-ply refers to the internal design of the tire. The plies (cords) run at the right-angle from bead to bead in this tire model. This diagonal design creates a rigid structure as it crisscrosses with each layer of the plying thread.

Bias-ply tires are sturdy, but the rigidity provides some fascinating handling features if you are used to driving on radial tires. The rigid structure implies that bias-ply tires do not offer efficient grip to the road surface like a radial tire.

As the tires follow the breaks and nuts in the pavement, it forms a “wandering” impression. Though this wandering is not dangerous, the drivers ought to be keener, especially at highway speeds.

Pros of Radial Tires

1. Tire Selection

Since radial tires are so popular, there is a lot of selection in terms of tire styles and sizes available. All-terrains, street tires, mud-terrains, and many more are available in a variety of sizes.

Therefore, car owners find it easy to choose a tire for their vehicles in whatever tire size they need. The tire styles are in another world.

2. Handling Performance

In terms of performance, radial tires are better. These tires are superior when it comes to handling sharp corners, making turns, and other performance operations.

On the other side, bias-ply tires do not react well to cornering forces, especially when the sidewall width increases.

3. Pavement Manners

There is no need to sugar-coat radial tires. These tires outshine their counterparts in everyday handling situations and on-pavement rides.

Indeed, this is the main reason why radial tires are the best choice for light trucks and cars ever since the early 1980s. Radial tires tend to skip over road irregularities such as cracks without transferring them to the vehicle.

Unlike bias-ply tires, radial tires do flat-spot mostly when the vehicle rests for some days. Therefore, radials are the best fit for daily driving.

4. Speed / Heat Dissipation

All tire manufacturers will tell their customers that the dangerous thing that will kill their tires are heat. An overheated tire can be due to several factors, including but not limited to speed, tire pressure, and weight.

As the vehicle moves, the tread face and sidewall of the tire move also. The higher the weights or, the faster the speeds, the faster the tire heats up. Radial tires are better for heat dissipation for several reasons.

Also, it is essential to note that the high-speed rating of a tire also means a low weight rating.

5. Traction

Radial tires are the best and most forgiving when it comes to working on terrain irregularities as there are fewer plies in the sidewall.

Due to less plies, a radial tire works best in all environmental conditions providing optimum traction.

Cons of Radial Tires

- More difficult to repair

- More complex and expensive to manufacture

- Bead cracks are common

- Rugged tread makes the tire noisy

- Curb impacts may lead to sidewall damage

- Steel belt design affects the ride quality

- Not best for negotiating rough or hilly terrain

- Pretty expensive than bias

Pros of Bias Ply Tyres

1. Traction

Bias-ply tires seem more robust and less prone to puncture. Therefore, most off-road drivers enjoy extra stiffness and better cut resistance.

Additionally, the bias ply tire design makes them better for more aggressive treads having wide spaces separating tread blocks. These tread patterns clean themselves out more easily than tightly spaced tread patterns with tread blocks packed close together.

2. Load-Carrying Capacity

Designed with multiple layers, bias-ply tires have the benefit in load-carrying capacity.

Since there are an equal number of plies to provide support to the weight of the vehicle in both the sidewall and the tread face, bias-ply tires are the best in handling heavy loads.

Due to this capability, tractor tires, trailer tires, and heavy equipment tires are almost always bias ply.

3. Puncture Resistance

Puncture resistance is the main reason why bias-ply tires are better for industrial, agricultural, and slow-speed off-road uses.

The sidewalls are not vulnerable due to the increased number of plies. Therefore, bias-ply tires are not as prone to puncture compared to radial tires.

4. Torque Splitting

Torque splitting, also known as zippering, is crucial for off-roaders. Though torque splitting is not a common term related to puncture resistance, it refers to damage leading to expanding or splitting under load.

For instance, if a puncture happens in the sidewall of a tire, the multiple layers will confine the break in the sidewall to the spot where the damage occurred. Therefore, the puncture on the tire will stay small which enables it to be temporarily repaired until a complete repair is done.

5. Big Tire Sizes

Though tire selection can be narrow, bias-ply tires lead the roost as they come in big sizes.

Most tires of about 42 inches in diameter and above are bias ply. Therefore, if big tires are your primary goal, then with no doubt, you are likely to end up rolling on bias-ply tires.

Cons of Bias Ply Tires

- Poor flexibility that reduces traction

- High rolling resistance affects fuel consumption

- Not fit for some shallow wheels

- Tread wears out faster

- Unable to absorb shocks from bumps

The Difference Between Radial And Bias-Ply Tires

Though there are many differences between radial and bias-ply tires, the main one is seen in their construction.

Radial tires are designed with cords running perpendicular to each other and have either steel or cording belts.

On the other hand, bias-ply tires are designed with nylon belts and overlapping polyester cords with a crisscross pattern of between 30 and 40 degrees.

| Radial tires | Bias-ply tires |

| Excellent traction | Weak traction |

| Susceptible to damage | The extra layer offers protection against damage |

| Smoother ride | Due to its stiffness, one would feel all the bumps in the road. |

| Expensive | Cheap |

| Difficult to repair | Much easier to repair |

| More durable | Less durable |

| Low load capacity | High load capacity |

Why Should You Choose One Instead of The Other?

Radial tires provide a better performance, comfort, and fuel consumption as compared to bias-ply tires. Although radial tires are more expensive, their durability and savings on fuel make them cheaper to use, especially for non-commercial vehicles.

However, most construction and agricultural machinery use bias-ply tires. Also, some classic car owners use bias-ply tires. Nevertheless, radial tires are the best deal if you don’t own heavy machinery or a classic car.

How Long Does Radial and Bias-Ply Tires Last?

Most trailers from the factories come out in radial-ply tires. Though they last for about 3 to 5 years, radial tires are made with a long-distance idea and can serve about 40,000 miles.

Bias-ply tires are designed for higher load capacity with extra plies and stiffened sidewalls. These tires can last for about 12,000 miles or between 3 to 5 years.

Though the tread wears down at a higher rate on bias-ply tires, you can drive about an average of 3,000 miles in a year with the trailer, so they are the best option for the money.

Can You Mix Bias-Ply And Radial Tires on The Same Vehicle?

Though it is not advisable to mix bias-ply tires and radial tires on the same vehicle, it can work well during certain race applications, when you want the car to behave in certain ways during the race.

Note that the difference in construction makes the tires react differently and may result in the vehicle losing stability.

How do I Know if The Tires on my Vehicle are Radial or Bias-Ply?

To know the type of tire you have, check on your tire’s sidewall where the specifications are written. If it is a bias tire, you will see a letter B on its specifications, while radial has the letter R. You should know that passenger cars do not use bias-ply tires for safety purposes.

Conclusion

To sum up the comparison between radial and bias-ply tires, radial tires seem to be the best option for most car, SUV, light truck and even bigger truck drivers in today’s world, while bias-ply seem to be the best option for heavier construction vehicles.

Hi, my name is Niklas, the head content creator & CEO of Whirling Wheelz. I am very interested in vehicles of all kinds, mainly cars. I have a car mechanics degree from high school and a big hobby of mine is to follow the WRC (World Rally Championship) both online and through travel.