Motorcycle rims are prone to a lot of wear and tear; therefore it is wise to maintain them in a good condition. One of the most essential ways to do so is powder coating them.

Powder coating involves smearing a dry powder on the surface of the metal. The powder sticks to the metal surface and then cured under heat, giving a durable finish. Powder coating helps to protect the metal from corrosion and protect the rims from damages such as scratches.

Motorcycle wheel powder coating typically costs between $100 and $200 per wheel. The typical price of powder may change depending on the square footage and rim depth of the wheel. The price will also depend on how many spokes there are.

For disassembly and reassembly, certain powder coaters could charge extra, but this is usually already included in the cost of powder coating a full wheel.

Why Powder Coat Your Motorcycle Rims?

Motorbikes can make excellent investments. They are a great way to travel around and can give you years of delight. To keep them operating efficiently, they also need routine maintenance.

The rims are one area that is frequently disregarded. Your motorcycle’s rims endure a lot of wear and tear from the road and the elements. This may result in them being harmed or corroded over time. Compared to typical liquid paint, powder coating has various benefits, such as superior color retention, greater durability, and increased resistance to oxidation and corrosion.

Your rims are given an additional layer of protection by powder coating, which keeps them looking brand-new for longer. Also, cleaning them becomes simpler because dirt and grime can no longer cling to the surface. This additional protection may be essential for riders whose bikes spend a lot of time in the sun.

Motorcycle owners may affordably personalize their bikes with various colors and finishes thanks to powder coating. The ability to choose a color that makes the rider’s bike stand out from the crowd makes powder painting rims a popular option. Therefore, powder painting your rims might be a simple and reasonably priced approach to give your bike some flair.

Cost To Powder Coat Rims

Always bear in mind that the length and diameter of your rims will determine how much it will cost to powder coat them. It will also depend on whether you want to hire a professional or do the work yourself.

Anyway, the cost of a base coat for powder painting rims ranges from $250 to $550. But only wheels with diameters of 13 to 26 inches and in standard, knockoff, and racing designs will be subject to this tariff. However, you will have to pay an additional fee of between $125 and $260 for a base coat with a glossy or candy finish.

There are other options if you don’t want to coat the rims by hand. Sending in your rims for coating is an option. In this case, you are responsible for the cost of the rims’ transportation to the powder coating dealer and their return.

Another choice is to powder coat your motorbike rims. The costs will vary substantially depending on the tools and equipment you now have and those you will need to buy in this case.

| Size of Rim | Cost per Wheel |

| 13 inches | $65 |

| 14 inches | $70 |

| 15 inches | $75 |

| 16 inches | $80 |

| 17 inches | $85 |

| 18 inches | $90 |

| 19 inches | $95 |

| 20 inches | $100 |

| 21 inches | $105 |

| 22 inches | $110 |

| 23 inches | $115 |

| 24 inches | $120 |

| 25 inches | $125 |

| 26 inches | $130 |

| Extra-Wide Racing Wheels | $87+ |

| Knock-Off Wheels | $50 |

| Steel or Aluminum Wheels | $62+ |

| Wire Wheels | $90 |

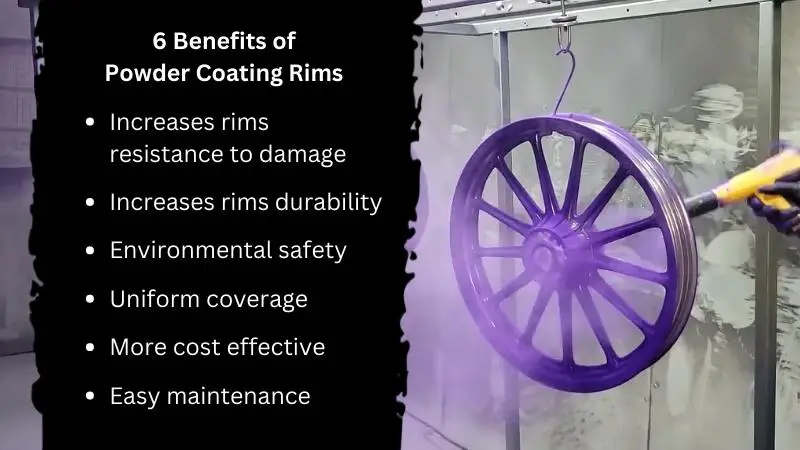

Benefits of Powder Coating Rims

Increases resistance to damage

The abrasive outdoors puts a lot of strain on wheel rims. Wheel rims can sustain damage from gravel, stones, and other road debris in addition to the environment’s chipping, scratching, flaking, and corrosion.

In contrast to traditional painting, powder coating forms a shield on the metal surface of your wheel rims, impervious to corrosion, chipping, and other damages. The result is a finish that will endure longer and withstand the elements.

Increases durability

High temperatures are used during the powder coating curing process to fuse the particles and firmly bond the coating to the metal’s surface. A solid, non-porous covering that is thicker and more durable is created by powder coating instead of paint, which only rests on the surface and is readily chipped away.

Environmental safety

Volatile organic compounds (VOCs), present in liquid paint, harm the ozone layer and, when exposed for an extended period, can have negative health effects on both people and animals. Since leftover paint cannot be collected and reused, painting also creates a lot of waste.

VOCs are not present in powder coating, which may be collected and used again. This is the more environmentally aware choice because it generates less trash and causes less harm to the environment.

Uniform coverage

Wheel rims can be intricate and frequently feature places that are challenging to paint, especially with traditional paint. This might result in regions that are painted unevenly or not at all, which damages the final product and makes your paint job more prone to flaking and chipping.

All parts of your wheel rims are completely coated thanks to the electrostatic charge of powder coating and the curing procedure. The end effect is a uniform, smooth finish that extends to every complicated angle and challenging location.

Cost-effective

Many customers paint their rims since conventional paint is less expensive than powder coating in the beginning. However, powder coating is more cost-effective in the long run when you take into account the waste produced during the painting process, the uneven coverage, the susceptibility to chips and scratches, and the requirement for re-coats.

Provides easy maintenance

Powder coating is simple to maintain and doesn’t require any specialized cleaners or solvents. Rust and other cleaning-related damage are not a problem because these coatings are resistant to corrosion and damage. In most applications, an occasional wipe with soapy water is sufficient to keep parts clean and functional for years to come.

Downsides of Powder Coating Rims

It’s quite thick

If your wheel has particularly complex detailing, that application of the mixture may dull it and fill in small spots. Additionally, powder coating can occasionally cause issues with your tires because it is a very thick layer on the metal surface that might diminish some of the definition of the wheel.

Particularly with low-profile tires, when the tire’s bead doesn’t fit snugly against the edge of the rim, air slowly leaks out, and the tire eventually goes flat. This may also influence your tyre size to some extent.

The higher charge for small projects

A provider might charge you more if they don’t have anything else to cover with the same color because it differs from spray painting. Smaller quantities cost more.

It isn’t easy to touch up

It’s preferable to have powder-coated rims cleaned back up and start from scratch rather than attempting to touch up little parts if they need some work.

Unbalanced color

Although the coating has a tendency to be quite uniform in thickness, when it has dried, thinner portions could have a slightly different color than thicker sections.

Can Any Wheel Be Powder Coated?

Almost any metallic surface, including most car wheels, can be coated with powder. Wheels made of steel, stainless steel, or aluminum can all be powder coated, however, treating the latter offers unique difficulties.

A set of aluminum wheels should be carefully considered before being powder coated. The temperatures required to cure powder-coated surfaces frequently exceed those used to heat treat metal wheels.

Therefore, in severe circumstances, the powder coating procedure could compromise the structural integrity of an aluminum wheel.

For this reason, many manufacturers cancel the warranty on any aluminum wheels sent in for powder coating. While individuals who have owned their car for a while shouldn’t have a problem with this, owners of vehicles still covered by the manufacturer’s guarantee should take caution.

In addition to a wheel’s makeup, the state of any rim intended for powder coating should be thoroughly examined. This is due to the fact that it can be challenging to evenly coat broken rims, which might result in a lot of cosmetic flaws.

How Does Powder Coating Work?

Typically, the powder is a thermoplastic or thermoset polymer. It is often electrostatically applied and then heated up to cure it.

A spray gun is often used to apply the powder. The powder is charged in the gun before being applied to the metal surface. The powder must then be dried. The type of powder used and the coating’s thickness affect how long things take to cure. However, at 200 degrees Fahrenheit, curing normally takes ten minutes.

How Long Does Powder Coating Last?

The majority of professionally applied powder-coated coatings typically have a lifespan of 15 to 20 years. However, this figure is also susceptible to fluctuation due to excessive UV exposure, severe wear and tear, and contact with corrosive substances.

This lifespan is almost twice as long as painted-on finishes, which, under ideal circumstances, have a projected service life of 5 to 10 years. The drawbacks associated with paint-based finishes still apply to powder-coated finishes.

Powder-coated wheels will fade and scratch over time due to normal wear and tear from the road. Regardless of the surface treatment, this kind of wear is normal for all rims.

Is Powder Coating Wheels Better Than Painting Them?

Most of the time, powder coating is considered to be preferable to painting a vehicle’s wheels. Typically, durability is the deciding factor.

A strong link between cured coatings and any metal base stock underneath is formed because powder-coated finishes are electrostatically applied. Paint, on the other hand, is just a surface treatment, which is a sharp difference.

Because of this, powder-coated finishes are much more durable than painted ones and rarely chip. Given the challenges of life on the road, this is crucial.

Additionally, powder coatings frequently apply uniformly and in a formal manner. Inconsistencies like thin areas or obvious flaws are infrequently a problem. Unfortunately, the majority of painted finishes cannot be claimed to be the same.

What Other Part Can You Powder Coat on a Motorcycle?

Your motorcycle’s components can be powder coated in addition to the wheels. In fact, powder coating can be applied to practically any metal component of your motorcycle. This includes the gas tank, handlebars, exhaust pipes, exhaust shields, control arms, swing arms, handlebars, and motorcycle frames.

Non-metal components like carbon fiber and plastic can also be powder coated. However, it’s crucial to remember that powder coating these components may violate applicable warranties. Therefore, if in doubt, constantly consult your owner’s handbook.

The complexity of the work typically affects how much the powder coating will cost. Additional fees will generally be if the job involves disassembling or removing many minor parts from an object. This is because it takes more time and effort to complete the task, and there is a higher potential for damage as a result. The more intricate the powder coating job, as with most things, the more expensive it will be.

Conclusion

Overall, knowing how much it costs to powder coat rims will be advantageous in the long term. These responses will help you decide whether to complete the project locally, through mail order, or on your own. They will also enable you to predict your future demands for powder coating.

Hi, my name is Niklas, the head content creator & CEO of Whirling Wheelz. I am very interested in vehicles of all kinds, mainly cars. I have a car mechanics degree from high school and a big hobby of mine is to follow the WRC (World Rally Championship) both online and through travel.