Like all other vehicle components, selecting your tires needs the same attention towards getting excellent performance and long life. The right tires will give your car better performance and you will save a lot of money on operation and maintenance.

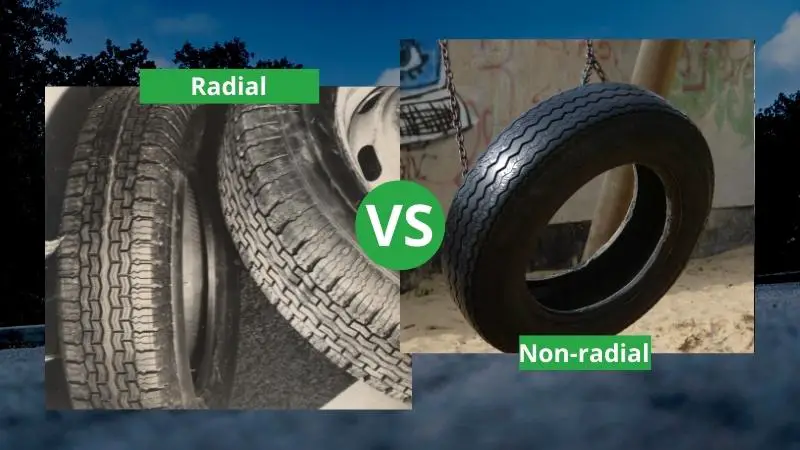

There are two types of tires, radial and non-radial which determine the level of performance a car will provide. These tires differ on many levels, especially the construction.

Please keep reading to understand the differences between these two constructions and how they impact daily road applications.

What is a radial tire?

A radial tire has non-crossed threads on the carcass cord but is organized radially. The cord threads are connected parallel to each other. These layers can be even or odd, and the tire can be tubed or tubeless. The sidewall of this tire has one or more cord layers with parallel threads. They are made from synthetic polyamide fabric that makes these tires extra strong.

The elasticity of the carcass and the lightness can also be harnessed for better performance. The upper layers of the tire carcass are covered with a steel belt.

History of radial tires

Arthur William Savage developed the first radial tire between 1915 and 1919. However, when Michelin acquired the patent for these radial tires, they were further designed to revolutionize the universe of radial tires. The ‘R’ symbol indicated on the side of the tire has been considered the standard marking in the industry for over 20 years to show the tire’s radial.

Nonetheless, radial mainly refers to the rigidity of the structure compared to the rubber. It also provides a rigid structural framework for the sidewall and the whole tire. Most radial tires have iron belts with polymer compounds built more profoundly into the tire frame. But they never work together with the tire contact surface in the entire grip.

Features

- It has a thread that protects the interior construction and provides enough grip on the roads. The structure offers longer life, durability, and maneuverability.

- Built with steel belts that make the tread stiff

- Has spiral layers for maneuverability and durability.

- Thick shoulders protect the interior from damages and shocks.

- Flexible side walls protect the interior and make the ride comfortable.

Pros

- Radial tires have a reasonable steering control due to their flexibility, which gives better vehicle control.

- They have a better contact sensitivity with the road surface because they have better grips and traction on the external tire surface.

- Radial tires are comfortable to drive because of the flexible sidewalls, which give shape when the tires are on the road surface and absorb bumps.

- They are good at resisting heat, especially when driving at higher speeds on a highway or a bad road section.

- It has a better fuel economy which saves money for the driver.

Cons

- The lateral stiffness of radial tires is low, which causes them to sway when speeding, thus resulting in poor stability.

- These tires are vulnerable to abuse when under-inflated or overloaded. These sidewalls will likely bulge and can cause puncture or damage to the tires.

- They have less shock absorption because the outside wall is built with a stiff steel belt.

What are non-radial tires?

Non-radial tires, also known as bias-ply tires, are built with a rubber-fabric casing and an airtight tube. The inner tube has to be inflated to make them functional. The sidewall uses asymmetrical construction that has evenly distributed crossed plies. Such tires have a structure where the ply cords stretch to the beads and are placed at alternating angles less than 90 degrees to the tread centerline. The cords are either nylon, polyester, or any other synthetic fabric.

It is highly resistant to cuts and impacts while being solid and responsive on rough roads.

Pros

- The stiff sidewalls improve the vehicle’s stability, making it easy to steer and handle when driving at low speeds.

- The tire construction is less complicated, which allows for easy fixing in case of damages. They also cost less than radial tires, which are more complex.

- The solid sidewall construction is strong enough to handle heavy loads even at high speeds.

- The rugged designs on the sidewalls are good for resisting punctures and cuts.

Cons

- The treads can easily be distorted when poorly handled over long periods.

- The single construction design can quickly explode under pressure because it flattens when subjected to stress.

- Because they do not have stiff steel cords, they tend to have a shorter life because they wear out quickly on all layers.

- Riders will feel all the bumpiness of the road

Why do some vehicles use non-radial tires?

Speed hunters who are after performance and speed need tires that can withstand extreme levels of stress and be responsive at the same time. The tires should also have positive feedback that a driver feels confident about. Touring and off-road drivers mostly go for features that make good use of the car, like load capacity and longevity of the tires.

They are primarily looking for a dependable vehicle that can carry heavy weights and manage shocks for long drives. There is only one type of tire that can meet the needs of both parties. Bias-ply (non-radial) tires are suitable for both conditions because of the stiff sidewalls. They perform well when subjected to heavy loads, and their lack of flex means that the sidewalls will not run out as fast as radial tires.

Non-radial tires are also the only tube-type tire available. Many drivers still fancy the classic look of these tires. When driving off-road, these tires also feel sturdier than cast wheels.

On the other hand, radials tend to beat non-radial tires in terms of their power to contribute to a substantially larger tread to sidewall ratio. Usually, the width of the tread and sidewall height have the exact dimensions as bias-ply tires. However, the radial construction supports these two dimensions to be significantly different. This means that a super-wide tire can be constructed entirely without a taller sidewall.

Radial tire construction has also revolutionized sports cars. With a substantially wide tread and a shorter sidewall, these tires have excellent feedback to drivers. They operate relatively calmly and have minimal flexing. Even though the sidewall may be thin with no sidewall flex, the tire can be rigid and solid, making it feel secure and planted, especially when cornering.

Differences between radial and non-radial tires

These are the main differences between radial and non-radial tires:

- Puncture and cut resistance

- Traction

- Ride quality

- Heat tolerance

- Tire-life cycle

- Load capacity

- Torque splitting

- Highway handling

- Performance

We will dive into why these things differ more thoroughly so keep reading

Puncture and cut resistance

Radial tires are highly resistant to cuts and indentations on the tread. This is because of the construction difference.

A radial tire is built with two parts; the casing has a rubber-coated steel cable layer that moves from one bead to the other. Other rubber-coated steel plies form the steel belts and are placed under the treads for crown stability.

A non-radial tire has layers of rubber-coated, crisscrossed plies and fabric built at a 30-degree angle. The formation forms a single working unit that can easily be deconstructed. However, the sidewalls are stiff and resist cuts.

Traction

Non-radial tires have one construction unit, meaning the sidewall deflection could force the treads to squeeze in and distort. This means that the contact patch will remain narrow when the tires are inflated due to the solid sidewall construction.

The construction of radial tires creates independence between the tread and the sidewall. Therefore, the tracks can remain flat and have an even contact patch distribution. This promotes excellent tractions and prolonged wear life.

Ride quality

Radial tires tend to have a smoother ride, increasing productivity for various types of equipment. The sidewalls on these tires flex easily to allow vertical deflection. At the same time, non-radial tires give a stable ride due to the tightness of the sidewall.

A sturdy sidewall keeps the loaders from moving up and down when carrying the maximum weight.

Heat tolerance

The combination of different tire materials produces other characteristics when subjected to pressure. Radial tires disperse more heat than non-radial/ bias-ply tires, which allows them to travel at higher speeds at a greater distance.

This is because the wooden treads and steel body ply construction without multiple nylon pipes facilitate heat control. When bias-ply tires are subjected to excess heat, they may deteriorate due to the single construction.

Tire-life cycle

The life cycle will determine whether it has favorable operation costs. A bias-ply tire will not offer the same life as a more expensive radial. Depending on the application, it can outlast a non-radial tire regardless of the sidewall construction.

Load capacity

Radial tires have different load ratings, with some being higher than bias tires. However, the weight-carrying capacity needs additional plies, making them very stiff. This makes them very complicated in terms of load capacity.

Unlike radial tires, non-radial tires have multiple layers which can handle excess loads. The number of plies is uniform and can support a vehicle’s weight by the sidewall and tread face.

Torque splitting

Torque splitting is of great concern for most off-road drivers. This refers to the level of injury splitting under excess load. A bias tire has a strong sidewall, so any puncture on the sidewall will not separate and break.

This is because it has multiple layers, which prevent the layers from splitting. Meanwhile, the construction of radial tires means the spot with the puncture will likely expand as more torque is applied. The original puncture will grow more prominent, further damaging the whole tire.

Every driver or car owner should consider these factors because a non-radial tire can easily be repaired with plugs before making significant repairs. Radial tires will further become more damaged, and the temporary plugs may not be effective. You will always have to travel with a spare tire in an emergency.

Highway handling

Radial tires are better than non-radial tires in everyday highway drive handling situations. This explains why radial tires are primarily used on vehicles and light trucks. Alternatively, bias-ply tires are notorious for rutting, cracking, and flattening when driving on uneven roads.

Performance

Vehicles experience much weight on the sidewalls when cornering, which explains why radial tires have good pavement manners.

They are also good at taking over sharp corners, maneuvers, and sweeping turns. Non-radial tires are poor at responding to cornering forces when the sidewall width is higher. In straight-line handling, both tires do not differ.

What are radial tires better for?

- Long drives – radial tires have a thinner profile which efficiently dissipates heat. This makes them the perfect option for traveling over long distances.

- Racing and Performance – The sidewalls on the radial tires are very flexible and do not deform the footprint. Such properties support significant maneuvering, traction, and cornering. High-speed vehicles can benefit greatly from excellent heat tolerance.

- Light trucks – Radial tires are built with steel belts, and these contribute to very sturdy construction. As long as they have a suitable load rating, this means they are good for light trucks that should carry moderate loads and manage regular driving.

- Highway driving – Heat tolerant wheels with flexible sidewalls and a wide footprint are suitable for driving on highways at higher speeds.

- Road trailers – Any radial tires with ST rates are suitable for trailers and can be used for highway and long trips. These tires rarely develop flat parts when parked longer.

Where should you use non-radial tires?

- Short trips – Non-radial tires are heavy-duty, but the thick construction makes them poor at handling the heat. You should only use them for shorter trips.

- Rough terrains – Whether you have a UTV/ATV, you need bias ply tires because they are rugged and less susceptible to punctures. They easily flex over uneven terrain and absorb most impact.

- Heavy loads – The stiff sidewalls can withstand the vehicle load, making them great for towing. They roll straight with less bouncing and swaying.

- Touring motorcycles – Thick non-radial sidewalls cannot be used on sports and racing bikes. However, if you have a touring bike, the ride is sturdy and comfortable.

- Lower speeds – A bias tire construction reduces the rolling resistance, and you will have less control when speeding. These are only good for driving at low speeds.

Understanding the quality differences between radial and non-radial tires forms an excellent basis for purchasing decisions. When buying car tires, you already understand your vehicle and know how to use it. Your vehicle qualities will determine whether the tires you choose will serve you as you wish. A radial tire will make your life easy if you live around the city because they are suitable for highways and last long in these conditions. Bias-ply tires/ non-radial tires are good for off-roaders who need a solid tire to maneuver through the different terrains.

Hi, my name is Niklas, the head content creator & CEO of Whirling Wheelz. I am very interested in vehicles of all kinds, mainly cars. I have a car mechanics degree from high school and a big hobby of mine is to follow the WRC (World Rally Championship) both online and through travel.