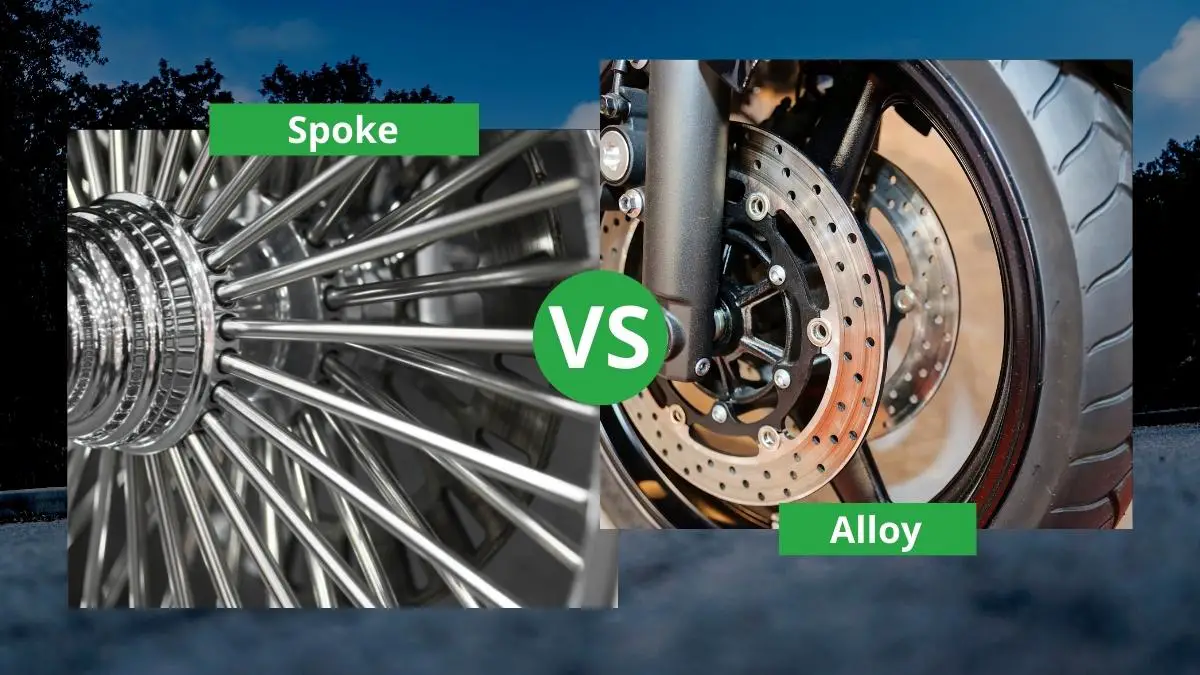

Motorcycle wheels can be wire-spoke or one-piece alloy. The wire-spoke wheels have been around for a long time until the 1970s when manufacturers realized the benefits of alloy wheels and how they were cheaper to produce.

With that said, each type of wheel has its applications. That explains why it is rare to find a sports bike or road tuner running on wire-spoke wheels.

Alternatively, adventure bikes still have wire-spoked wheels because they provide sufficient rigidity for challenging roads.

Now that you know the differences between the wheels, let’s look at each category’s advantages and disadvantages.

What Are Spoke Wheels?

What is a spoke? A spoke is a rod that radiates from the wheel’s center to connect the hub with the surface.

Spokes can transfer the rider’s and motorcycle’s weight between the rim and the hub because they are strong.

Spoke wheels are constructed by bending a steel rim in shape and connecting wire spokes to the inner hub and outer rim. Spoke wheels are mostly hand-assembled with machinery only when testing stability.

Wire-spoked wheels built from aluminum and steel are primarily used in adventure and dual sport bikes because they are more elastic and durable. They can easily absorb impact from rough terrains and bumpy roads. Considering it is easy to repair the spoke wheels, they are more practical.

Advantages of Spoke Wheels

1. Wired Spokes are Durable

The individual steel spokes can withstand massive tension, considering the multiple pressure points. In addition, the wire-spoked wheels are more durable on challenging terrains by offering strength in three planes.

- Radial; Helps resist deformation when the tire hits a pothole

- Lateral; limited side-to-side movement because bikers lean over when turning

- Axial; Transfers drive and braking force from the hub to the outer wheel and is proportional to the number of spokes crossing on each side

Most modern adventure bikes have cast or spun aluminum rims that bend before breaking.

2. Elastic and Flexible

Because these wheels are steel, the spokes are elastic and can absorb some of the jarring on rough roads. It can also absorb the impact of hitting holes or obstacles to prevent the wheel from breaking while lessening the impact on the rest of the bike and rider.

3. Wheels are Repairable

When impact or poor maintenance damages spoked wheels over time, a professional wheel builder can return them to their former glory. Doing this saves a lot of money because it cuts the costs of replacing the whole hub and rib. In addition, if the rider cannot access a repair shop, they can band the bent rim into shape within a short time to adjust the tension on the appropriate strokes.

4. Considerable Lightweight

While this might be controversial, some spoke bike wheels weigh less. However, it does not impact the bike’s weight because you cannot feel the heavier tires when you traverse the road. The un-sprung weight of the wheel is also not significant as the weight higher up on the bike.

5. Less-Costly Wheels

Since all weight is relative, manufacturing spoke wheels from steel, magnesium, and aluminum could be cheaper. However, since the wheels are labor-intensive and complex to build, the higher price tags could compensate for the heavy manpower input.

6. Spokes Look Appealing

Wire-spoked wheels look better on most bikes, especially adventure bikes. Some of the best mid-sized and big adventure bikes have spokes that are great for both tarmac and dirt roads. However, solid cast alloys are also strong but may not do well on certain roads besides not having greater aesthetics.

7. Tires Easily Seat on the Bead

Wire-spoked wheels mostly run on tires with tubes. The tubed tires are easier to seat on the bead than tubeless tires, making everything easier for roadside repairs when installing a new tube.

Disadvantages of Spoked Motorcycle Wheels

1. Constant Maintenance

The wheel spokes are constantly under high tension and must be inspected frequently and adjusted where necessary (known as truing). In addition, damaged spokes need immediate replacements to avoid straining the other functional spoke and reduce uneven tension on the rim.

2. Specialized Skills for Spokes Replacement

Although adjusting tensions on bike spokes is easy, it requires special skills to do things perfectly. Likewise, rebuilding an entire wheel requires specialized services to put everything in order.

3. Spoked Wheels are Susceptible to Breaking

Spoke wheels are preferable because they are durable. However, this means that they can fail to unprecedented degrees. When these spokes break, the wheel can collapse and cause accidents.

4. Frequent Punctures and Blowouts

Spoke motorcycle wheels require tube-type tires because of the drilled holes in the rims where they attach the spokes. Therefore, in case of a puncture, you must remove the wheel and repair or replace the inner tube. Tubeless tires are easier to pull out from the outside when on the road.

A blowout is likely to happen at high speeds because the tube gets hot due to friction when running at lower pressures. Once it bursts, it instantly loses all the air, resulting in an uncontrollable bike. However, tubeless tires rarely lose pressure because there is only one hole that allows air escape.

5. Instability at High Speeds

Spoked rims are very flexible for absorbing impacts and bumps, which reduces stability at higher speeds. However, riding at nationally allowed speed limits should not be an issue. Only worry if you have poorly maintained spokes.

6. Spoke Wheels are Hard to Clean

If you like cleaning your bike frequently, prepare for spoked wheels to keep you busy. Cleaning behind every spoke can be very tedious, especially if you want to polish them. Also, exposure to mud and water can cause rusting, which can be hard to restore.

7. Tricky to Connect the Pump Hose

Some gas station pump nozzles barely fit onto the valve stem of spoke bike wheels. However, you can overcome this challenge by rolling the wheel to access the valve and threading the pump nozzle the spokes in the widest area to allow a straight fit on the valve.

What Are Alloy Wheels?

Alloy wheels combine metals like aluminum, magnesium, or nickel. An alloy combines metals or other elements to build a solid structure.

Unlike pure metals, alloys have a wide melting range in which the substance is a mix of liquid and solid. This construction explains why these alloys provide a greater strength advantage over pure metals that are malleable and softer.

Alloy wheels are rigid and can handle higher amounts of torque and horsepower without bending. They also happen to be smoother and predictable when riding in fast corners. These pros make the wheel a great option for speed bikes.

Advantages of Alloy Wheels

1. Compatible with Tubeless Tires

Cast alloy wheels on a motorcycle can easily fit tubeless tires because they only have one hole that seals the passage of the valve stem. Tubeless tires are also safer due to the low risk of a blowout and can be easy to fix.

2. Alloy Wheels are Cheaper

Cast wheels are created through automatic manufacturing processes, meaning hundreds of wheels are producible within a short time. Motorcycle manufacturers switched to cast wheels in the 1970s and 1980s because of quick production. On the other hand, spoke wheels need a lot of effort because each spoke must be threaded by hand to set the tension. The overall product is therefore cheaper.

3. Wheels are Rigid

Cast wheels are more rigid than wire-spoke wheels, so they can easily transfer power to the road efficiently and remains stable at higher speeds. This explains why there are no superbikes with spoked wheels.

4. Cast Wheels Stay True

There are no further adjustments a rider can make on a one-piece motorcycle wheel, so they will always stay true. Therefore, they do not require tedious maintenance services to keep them running throughout.

5. Alloy Wheels Come in Different Designs

Cast wheels can take after different designs to improve aerodynamics for high speeds and to fit any motorcycle. The wheels are also paintable depending on the owner’s wants.

6. Wider Tires Can Fit Cast Wheels

Cast alloys can conform to wider tires than wire-spoke wheels that are limited to the angle of spokes. This is greatly useful for rear tires on superbikes and large cruisers.

7. Wheels can be Lighter

Alloys wheels can be made from carbon fiber to make them lighter for various racing purposes.

Disadvantages of Alloy Wheels

1. Damaged Cast Wheels Can be Disastrous

When you hit a ditch or a pothole with a cast alloy wheel, it can break or crack because it is brittle and rigid. Unfortunately, once the wheel is damaged, it becomes unrepairable when traveling. In most cases, only a machine shop can repair the wheel; if not, you will need replacement wheels.

2. Alloys are Less Flexible

The inflexibility of alloys makes them unresponsive to impact and obstacles, even on uneven roads. This can cause discomfort or damage to other parts of the bike.

3. Wheels Go Out of Balance During Impact

When an alloy wheel hits a curb or a rock, the dent could cause an imbalance. This further causes vibration, easily tightening on a spoke bike. In severe cases, you must balance the wheels.

4. They are not Off-Road Friendly

Cast or forged alloy wheels may look cool on a new bike on the tarmac. However, the performance will be different during off-road riding. The rocks, roots, and fallen branches may cause more damage to the wheels.

Differences Between Spoke and Alloy Motorcycle Wheels

1. Construction Differences

An alloy wheel consists of a single metallic block, unlike a spoke wheel with a rim connected to a hub with several spokes. Alloy wheels are lightweight due to the mix of metals but spoke wheels tend to be heavier because they are heavy steel.

The lightweight alloy materials are strong enough to handle stress from all directions when a motorcycle is on the road. In addition, the metal composition of aluminum and magnesium makes the wheel less expensive while being ultra-light for racing purposes.

Alloy wheels are either cast or forged, where cast alloys are made by pouring molten alloy into a pre-fabricated cast and then left to cool. After the metal cools down, the cast is detached to remove the newly cast wheel inside. Alternatively, spoke wheels are products of heavier steel which makes them expensive.

2. Performance Differences

Spoke wheels are compulsory for off-road bikes like enduros, dirt bikes, scramblers, and ADVS because they are more durable than single-piece cast wheels. However, they are not friendly to large rocks, massive ruts, and occasional potholes. On the other hand, they can bend and flex to a given degree, allowing the rider to maneuver through rough terrains.

On the other hand, alloy wheels are more rigid for handling higher speeds and higher amounts of horsepower and torque easily. The solid, inflexible design makes the single-piece wheel great for turning at higher cornering speeds while remaining stable and consistent.

3. Cost and Maintenance Differences

There is an inverse relationship between alloy and spoke wheels regarding cost and maintenance. Spoked wheels have a complicated architecture that may need human input to connect the spokes from the rim to the center hub.

This explains why this wheel species is more expensive than alloy wheels made in the thousands by a machine. Since alloy wheels are cheaper to produce on a large scale, it explains their popularity.

When riding out in the hills and happen to dent or bend a spoke on the wheel, it is easier and cheaper to replace the individual part. Unfortunately, these wheels have inner tubes, so if you have a flat, it makes trail fixes more time-consuming.

Alternatively, if you hit a curb or jump into a pothole with your alloy wheels, any cracks or dents mean the entire wheel needs a replacement. In the case of a flat, the alloys are mostly tubeless, meaning you can easily fix a flat and get back riding within minutes.

Summary

When looking at the differences, advantages, and disadvantages of spoke and alloy wheels, you realize there is no one-size-fits-all solution. Each of these wheels is better depending on your bike type.

Alloy wheels are preferable because the tubeless tires are lighter and easier to fix during a puncture. Quick fixes save time and money compared to having a wheel with an inner tube.

Spoke wheels might be heavier, but they work better for adventure bikes. While they can be challenging to fix, replacing the wheel takes only a small part.

So, for performance-oriented road bikes, cast-alloy wheels are better. Spear wheels work better when considering off-roader motorcycles that can move in difficult conditions.

Hi, my name is Niklas, the head content creator & CEO of Whirling Wheelz. I am very interested in vehicles of all kinds, mainly cars. I have a car mechanics degree from high school and a big hobby of mine is to follow the WRC (World Rally Championship) both online and through travel.